Our Software

SAT Process

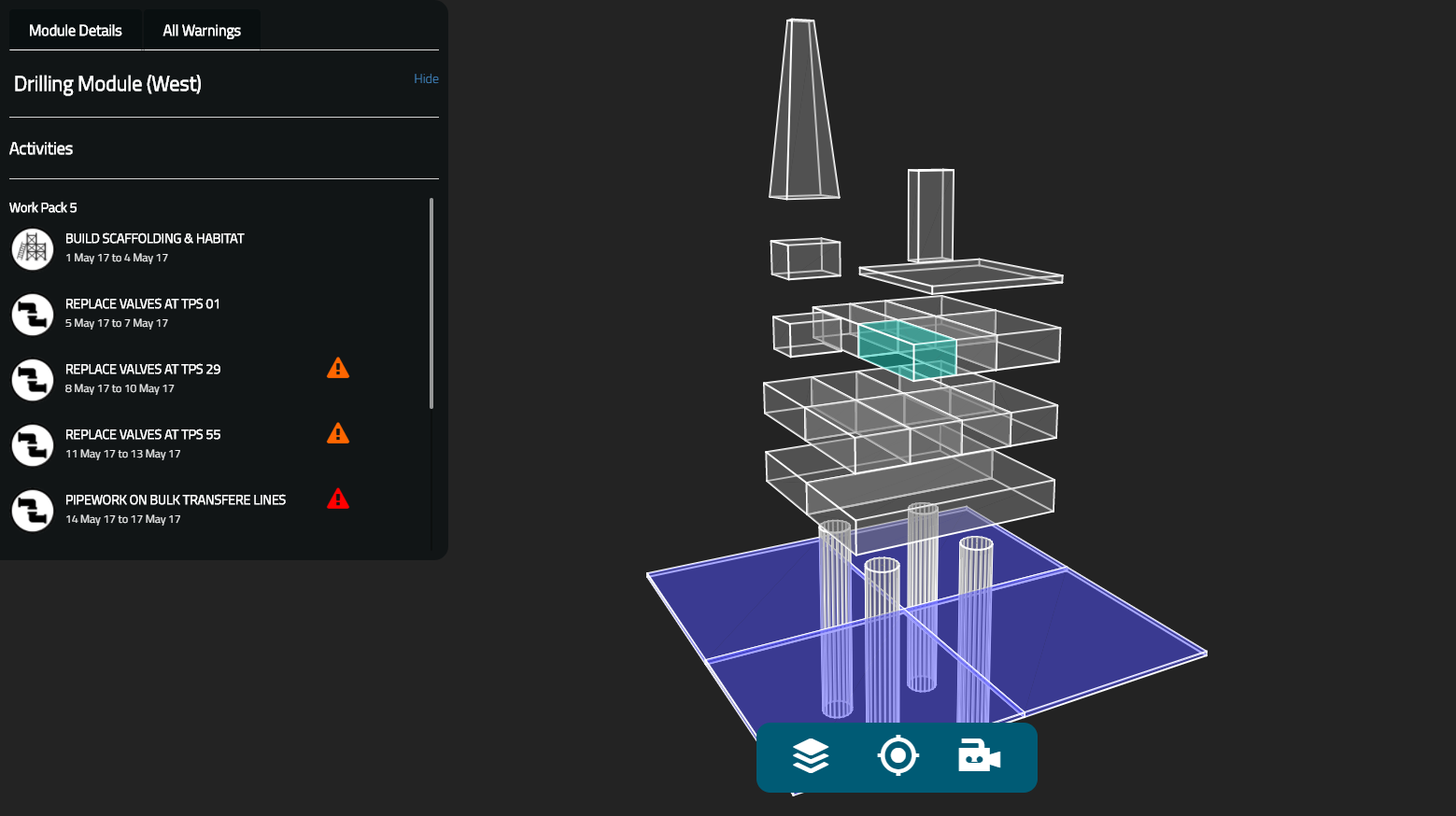

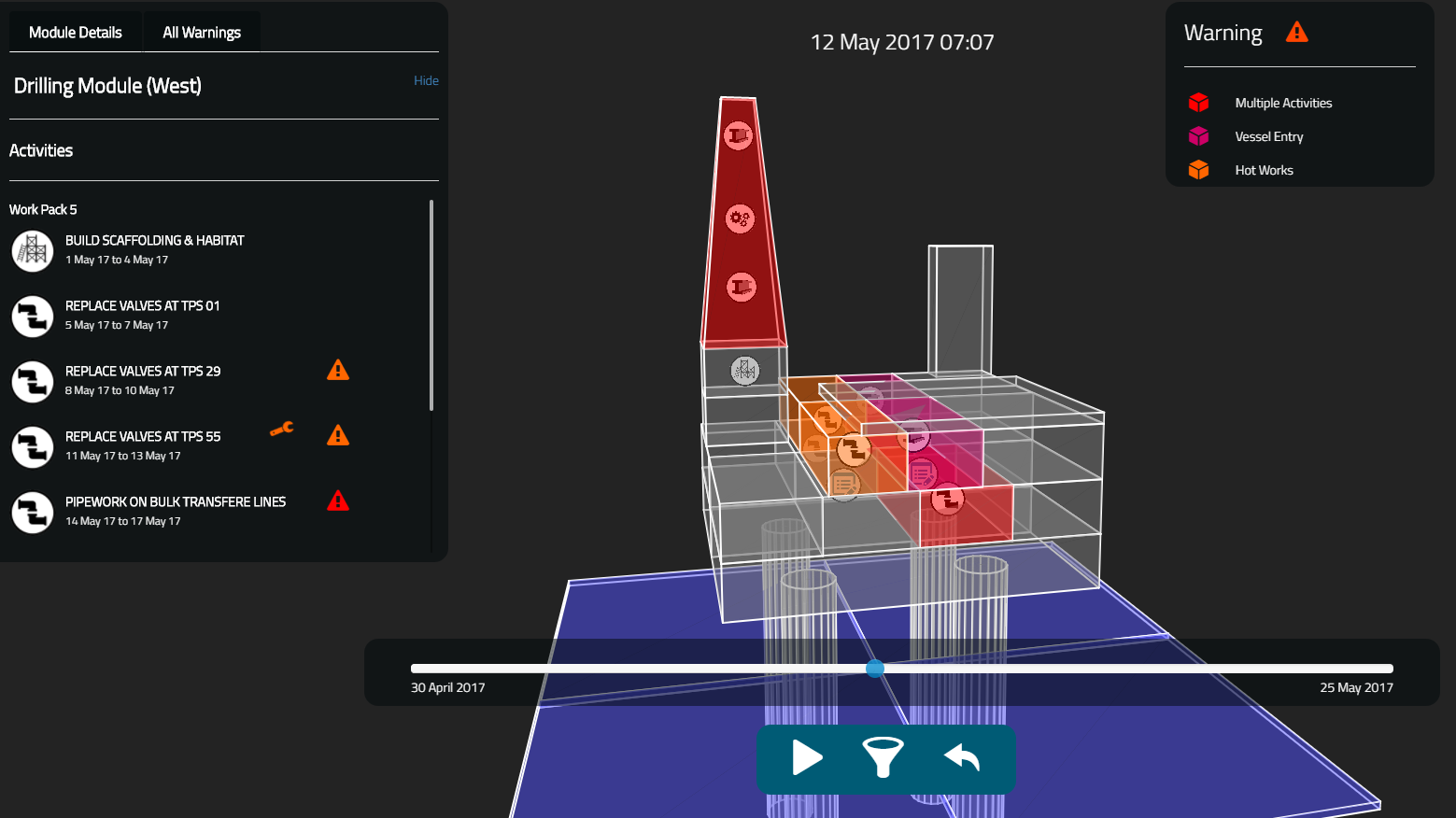

SAT Process is Cambla's second software offering. Creating a visual representation of a process installation, for example an offshore platform or refinery, the software allows users to place and track work of various types within the asset. Potential issues with work place saturation and conflicting work will be detected and highlighted for the user, helping to ensure work is carried out on time and safely.

Why use SAT Process?

SAT Process is a new software tool developed after hearing from a number of industry professionals that there is a need for a planning support tool for scheduling work carried out on assets. SAT Process allows for an unparalleled level of engagement and interaction with work schedules making even complex plans far more comprehensible. The software helps find situations where an area may have too many people working within it at any one time or if work has been scheduled to be carried out in an area too close to another area that is undergoing conflicting work. Checks relating to marine vessel approaches are also carried out for offshore assets, ensuring that over the side work takes place only when it is safe to do so.

- SAT saves our clients a significant amount of man-hours by taking away the need for reviewing paper based Gantt chart schedules which can be time-consuming, cumbersome and error-prone.

- The SAT visual animation is an effective way of building consensus and engagement within the project team, ensuring everyone is aligned to the same schedule. It is a particularly valuable tool for those who are not accustomed to reading schedules.

- The animation can be easily and quickly updated after the first version has been imported, changes to your plan will take only a few minutes to get in to SAT.

- Cambla can provide face-to-face training to help get you started and will support you to make sure you get the most out of the tool.

How it works

The first step is to create a model of the asset. All the modules or areas of the facility are shaped and then dragged and dropped into position until all the areas that you need to work with are present. From there, a work schedule is taken from planning software, whether this be Primavera P6, Microsoft Project or Safran, and is coded up to help the tool understand the plan. SAT Process takes this schedule information and applies it to the model of the asset allowing users to view the work being carried out through a timeline. This plan can be updated at any time as it changes.

Cambla can provide training to anyone in your organisation that will be making use of the tool and will provide the support you need to get the most out of SAT Process. Once plans are imported they can be viewed by anyone in your team at any time online and they'll always be able to access the most up-to-date version of the plan.

Each model allows:

- See work schedules for all of your assets

- Ensure no one area has too many pieces of work at any given time

- Check that hot work and vessel entry limits are not exceeded

- Resolution of claims and input to forensic planning

- Can be used for a wide range of facility types for example offshore, onshore, nuclear, chemicals and more

- If you have specific needs let us know and we can show you how SAT Process can work for you

Want to know more?

This new software tool is designed by planners, for planners, to make life easier when scheduling topside based work.

If you want to discuss the features of SAT Process and find out how it can help you with planning please get in touch - alexander.macleod@cambla.co.uk

Trial our software

To view a demo of the SAT Process tool click the button below and enter the following details:

Username: CamblaDemo

Password: password

SAT Process Log-In